Custom injection moulding is often a specialised method that will allow suppliers to generate plastic areas and components built to fulfill certain requirements. Contrary to regular injection moulding, which generally produces off-the-shelf things, tailor made injection moulding is about overall flexibility, precision, and innovation. It’s well suited for corporations that demand exceptional shapes, components, or features within just their solutions.

What exactly is Custom made Injection Moulding?

Custom made injection moulding includes building a bespoke mould and picking out correct elements to build components which are customized to some consumer’s technical specs. This process begins with a detailed structure stage, normally employing Computer-Aided Style and design (CAD) computer software, accompanied by the fabrication of the personalized tool or die. After the mould is finished, molten plastic is injected with it pressurized, forming a distinctive ingredient that matches the construction specifically.

Advantages of Custom made Moulding

The principal take pleasure in customized injection moulding would be the capability to generate highly specialised pieces. Whether it’s a posh condition, a good tolerance, or even a distinct material necessity, this process can provide success that off-the-shelf elements simply cannot match. It also offers large repeatability, making sure Every portion is dependable in top quality and general performance.

Customized moulding is In addition scalable. After the initial mould is completed, it click here may be used to deliver hundreds together with millions of equivalent areas effectively. This can make it a cost-productive Remedy for long-expression production, build upfront tooling expenses are bigger.

Programs in Field

Customized injection moulding is utilized across lots of industries, such as automotive, clinical, consumer electronics, and industrial products. By way of example, a professional medical gadget firm might need a plastic casing with crafted-in antimicrobial Attributes, though an automotive company could possibly have to have substantial-power components resistance in opposition to heat and chemicals.

Product Possibilities

Yet another benefit of customized injection moulding would be the array of materials offered. From rigid ABS and impact-resistant Polycarbonate to adaptable TPU and chemical-resistant Nylon, consumers can choose the plastic that matches their application.

Partnering with Authorities

Functioning Together with the professional injection moulding company like Australian Consolidated Plastics assists to make certain each individual phase—from layout and prototyping to tooling and generation—is dealt with with knowledge. Their electricity to offer end-to-close aid can help consumers minimize improvement some time to bring solutions to market place faster.

Conclusion

Custom injection moulding is really a highly effective manufacturing Resolution that gives precision, flexibility, and efficiency. Irrespective of whether for prototyping or huge-scale generation, it permits businesses to alter ground breaking Suggestions into large-excellent plastic products and solutions tailored on their own specific requires.

Rick Moranis Then & Now!

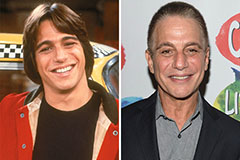

Rick Moranis Then & Now! Tony Danza Then & Now!

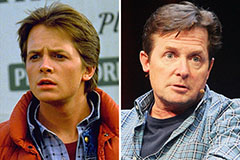

Tony Danza Then & Now! Michael J. Fox Then & Now!

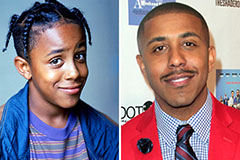

Michael J. Fox Then & Now! Marques Houston Then & Now!

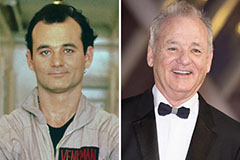

Marques Houston Then & Now! Bill Murray Then & Now!

Bill Murray Then & Now!